Thinking, insights, and News.NYCD team never stop thinking of innovation.

9 Industrial Design Trends for Desktop Machines in 2025

Under the current situation of high labor costs in North America, the global demand for small tool-type products from makers and small B-end customers is exploding. Accompanying this is the smoke of battle in the Amazon processing machine category and its internalization. Is ID design choosing popular styles with thin profits but high sales to expand market share, or is it extreme innovation?

To help you grasp the R&D trends of 2025, this "Desktop Tool Product ID Design Trend Report" will answer your questions:

What are some new products, new designs, and new trends in desktop-level tools?

How to understand the trends that the audience of Western desktop tool products are focusing on?

How to carefully control design costs for the European and American markets?

In terms of design trends, desktop-level devices have shown many common design features, which is a topic faced by many manufacturers, and also the research target of designers and product managers.

2025 Desktop-Level Tool Design Trends

The Revival of Carbon Dioxide Laser Cutting Machine

The rise of laser welding machine category.

A type of shutter for galvanometer laser

CNC machine providing wood carving solutions

Meet the folding requirements for outdoor use

Lighter, faster, and more user-friendly industrial design color scheme

DTF Printer, Heat Press Machine

Satisfying Global Manufacturability

AI Copyright: Thinking about Creativity in Industrial Design

1. CO2 Laser Cutting Machines Renaissance

When talking about most significant design trend in 2025, it is undoubtedly the intensified competition of CO2 large-scale high-power laser cutting machines.

Naiyang Creative Design Forecast: In the desktop laser market, semiconductor (diode) lasers are the widely preferred choice for low-cost market dominance. However, in today's saturated product market, delivering higher power requires CO2 type lasers to break the deadlock. Therefore, the competition for industrial laser cutting machines with more than 50W is increasing.

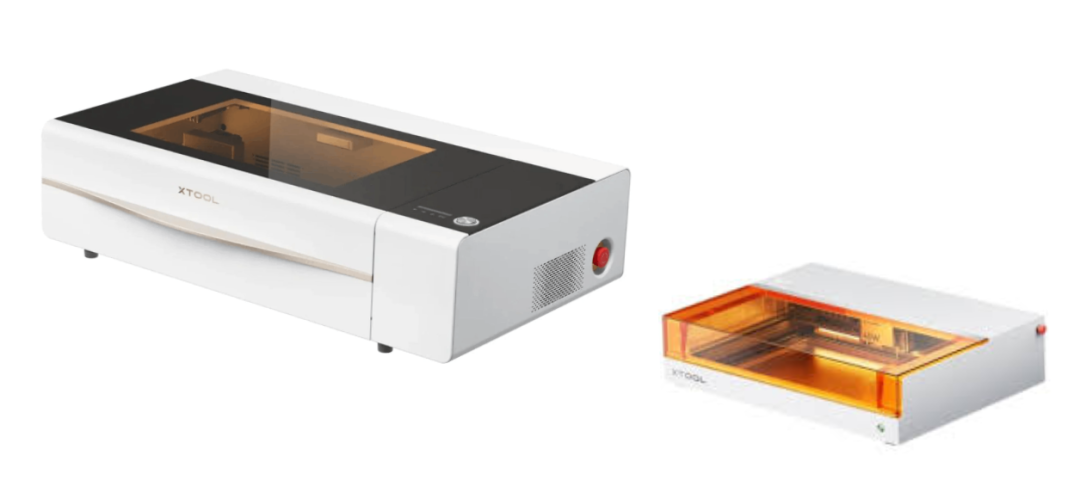

The ID appearance upgrade of the CO2 laser cutting machine will become a new market focus in 2025. The product design needs to tell a good story of delivering powerful cutting capabilities at a low price, such as the xTool P2 laser efficiently processing large materials, such as door panels, furniture components, and large logs.

xTool's P2 continues the success of the P1 design by NYCD

Senior American laser DIY maker, Schroeder predicts: In the field of CO2 lasers, high-power desktop-level in the 75W-125W range will become the new battlefield for attacking the industrial level. There is significant room for improvement in the appearance of traditional industrial cutting machines.

Traditional Industrial Laser Engraver Design

Former R&D head of xTool D1 predicts: Surpassing 50W of high-power CO2 is the key driving force for future sales growth. Not only because it can meet more efficient production needs, but also because they can provide manufacturers with a more considerable power-cost ratio.

In this way, a friendly appearance design is necessary and can significantly improve the user operation experience.

Major manufacturers have begun exterior upgrades at the 50W level

NYCD design agency's project xTool P1, wraps a 'traditional' industrial machine, with a sense of modern and minimalist body shape.

Its impressive appearance has established a leading position in the 40W laser cutting machine market, revealing the direction of a type of safety regulation laser development. It has won the Red Dot Design Award, significantly improving the product brand image and conversion rate.

P1 that won the Red Dot Design Award

NYCD design agency believes that ultra-high power desktop devices will continue to develop. He will continue to use professional experience in the field of industrial design to work with a wide range of companies to promote new product development.

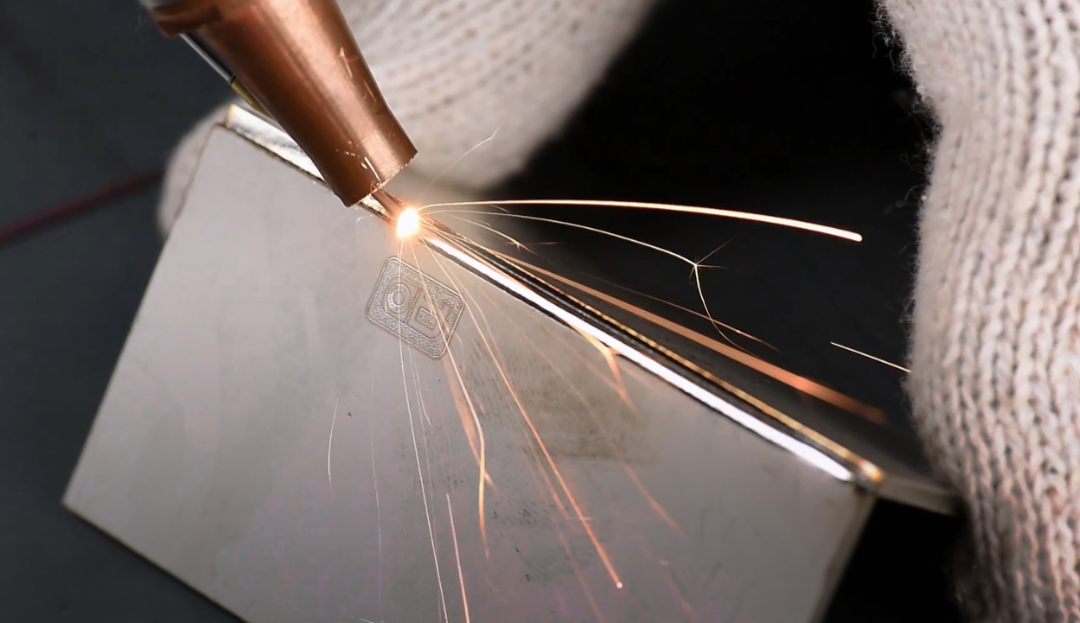

2. New Welding Machine Category:

In 2025, another design direction to avoid falling into power competition is the laser welding machine category. Through the "miniaturization design" in appearance, there is an opportunity to create a creative explosion for B-end customers in North American small factories.

Manufacturers are completing the product chain beyond laser cutting, delivering comprehensive laser solutions to small and medium-sized enterprise users. This inevitably requires the use of industrial design to create a more portable appearance, a more user-friendly experience, and a refined body design.

By 2025, emerging laser brands such as THEO, SFX, HRlaser, etc., have the opportunity to start a comprehensive competition in the consumer market in the product range of over 1200W light power.

Naiyang creative designers know well that the cost of laser welding machines significantly exceeds that of cutting machines, so it is very necessary to provide a friendly ID appearance and innovative structural design.

With full involvement of major tool manufacturers, by 2025, welding machines will inevitably welcome a small climax in appearance upgrades. Equipment, which used to be square and straight, has been enhanced with modern smooth elements, evolving towards refined desktop products, maintaining professionalism without losing modern aesthetics.

3 Deep Digging Folding Innovation:

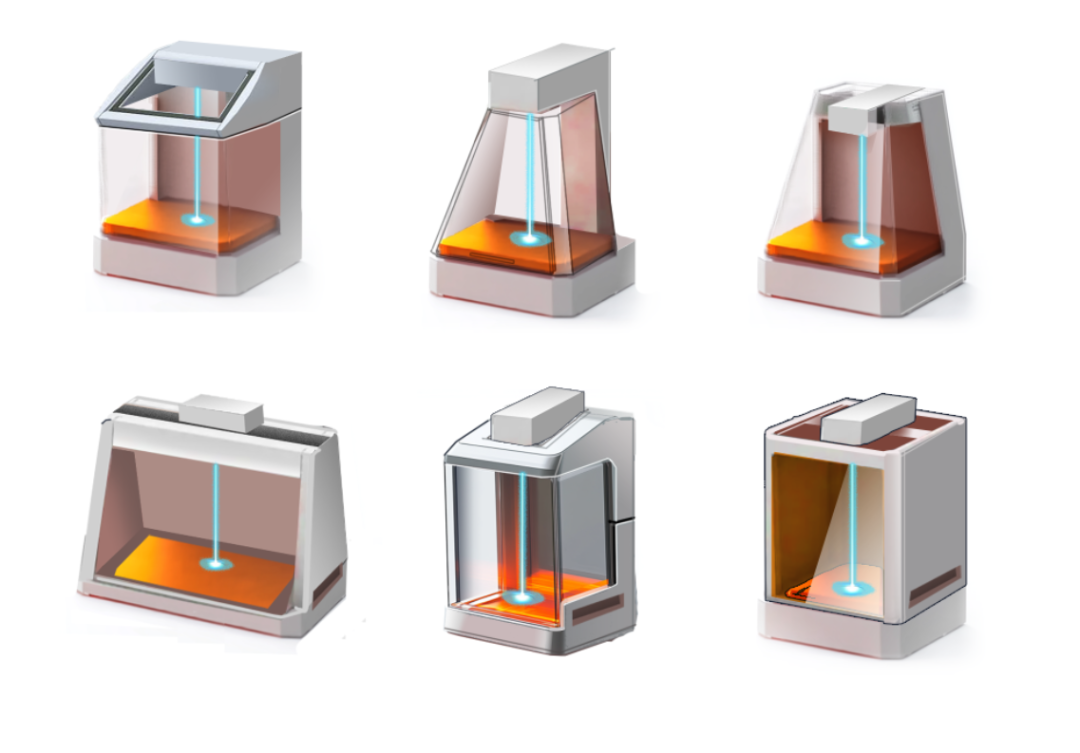

Play method of the shutter of the galvanometer laser equipment

"The year 2025 will be a year of exploring folding innovations with Fiber lasers." Cody, the Director of Market Strategy at Naiyang Creative, believes: "Folding innovation is not just to meet a type of laser safety standard for light shields, but also to combine industrial design to provide customers with a richer and more natural operating experience."

The current design paradigm in the market is undoubtedly the xTool F1 Ultra, which has truly initiated a category of shading masks, broadening product design scenarios, and becoming an industry innovation benchmark.

How to make the galvanometer laser portable, and elegantly unfold into a class of safety regulation working state? Answering this design question can make the product adaptable to more environments, becoming a desktop creative tool that enters thousands of households.

NYCD has collaborated with a large number of laser factory customers to explore many ingenious designs of folding mechanisms, allowing the equipment to blend into the environment with innovative folding methods without sacrificing safety certification requirements.

These honeycomb panels and light shields are usually equipped with micro switches, which monitor emergency stops in real time during operation to ensure safety. This means that whether you are a novice in laser technology or an experienced craftsman, you can safely express your creative talents.

04 Deep Processing of Wood:

CNC Desktop Devices

When discussing laser pre-processing technology, we often focus on its accuracy and engraving speed. But if we turn our perspective to woodworking deep processing and three-dimensional carving, we will discover a new creative category - CNC router.

Before the emergence of the laser cutting machine market, CNC engraving machines were already widely available. Despite the continuous power upgrades of laser cutting machines, they still struggle with more three-dimensional and deep engraving.

Despite the significant growth in the laser processing market, customers in Europe and America have never taken their eyes off CNC, instead actively exploring the best processing combination of CNC and laser cutting machines.

Naiyang Creative Design believes: Through carefully crafted CNC industrial design, it is entirely possible to create innovative products more suitable for the consumer market, providing a new product grasp for the processing equipment market.

Embrace Craft Fair Creative Market

The next trend of Naiyang Creative is more comprehensive, surpassing the style of a single product category.

Outdoor woodworking show off has become a popular lifestyle trend. In the context of tool-related scenes in North America, Google Trend searches for the Craft market have increased by 1/3 compared to 2022. Why is this growth so significant? The reason is that more and more craft practitioners (SMB customers) are eager to display and sell their woodworking works at open-air markets.

Typical Outdoor Wood Art DIY Markets in US

Traditionally, laser machines are designed for indoor use only, requiring fixed installation and complex smoke extraction equipment. However, for woodworkers and craft enthusiasts who enjoy outdoor activities, product design can be fully expanded to outdoor scenarios, providing a better processing and demonstration experience at open-air creative markets.

The industrial design challenges behind this are not small. Considering the instability of outdoor use, including how to design a wide base to prevent tipping, how to compress the size to meet portability requirements, and how to make the color meet the fashion tone of the Craft fair.

In order to effectively mine customer needs, it is very necessary to reshape outdoor products with industrial design. By 2025, craftsmen will be able to see product designs that better match their creative identities.

06 Light Color for Home Decor

Setting aside the maker filter of the tool-oriented crowd, the conclusion that processing equipment can only be placed in garages and workshops may not necessarily be true.

Imagine, your CNC equipment is not placed in the garage or warehouse, but a product perfectly integrated with the home environment. In 2025, when a type of safety standard is popularized and air purification becomes standard, this trend is not out of reach.

xTool P1, Designed by NYCD, color perfectly into the home environment

NYCD values the US market's pursuit of product aesthetics and brand premium. It introduces the design concept of white appliances into industrial design, giving vitality to the processing equipment brand. White as the main color tone, integrated with the home environment, will not appear abrupt, and can bring a simple and high-end visual experience.

This trend has been validated by new products from manufacturers such as xTool, OMtech, Gweike, etc. - the continuous introduction of simplicity + light color direction is precisely the fashion statement of defining processing equipment as household appliances.

xTool's product CMF Design Strategy has a continuous trend of returning to white home appliances.

The CMF style of industrial equipment was deep and black with bright yellow warning tone, but this CMF rule is changing.

The market is increasingly expecting the "house aesthetics" that can be integrated into the home environment. NYCD follows this trend and continues to explore how to define the appearance through the CMF material trend, helping your product tell the story of brand rejuvenation.

7.Entering clothing DTF/DTG market: Color Printers

Desktop-level processing equipment can mostly handle Vinyl and printing, which has unlocked the niche market of DTG/DTF garment printing machines for major manufacturers.

Currently, this category is dominated by leading manufacturers such as EPSON+Brother. As Mr. Zhang of a clothing design company in Guangzhou said, "The clothing industry requires very stable print quality, while also needing to meet production capacity requirements. Good customer support and high device fault tolerance" are crucial.

Epson SureColor F2270 Hybrid DTF and DTG Printer

The design concept of this type of DTF/DTG device is actually quite clear, with competition focusing on delivering stable quality, lowering operational thresholds, and meeting the needs of B-end customers. Mastering the operation of the equipment in a short time is the key to maintaining profitability and gaining corporate recognition - essentially, it's about how to replicate the success story of similar devices like xTool D1.

Although it is extremely difficult to benchmark against top manufacturers like EPSON in a short period of time, this also provides an opportunity for desktop tool equipment manufacturers to plan ahead, break away from the original product line, and strive for apparel enterprise users, achieving overtaking on a curve - DTF and DTG equipment are worth redoing with high-quality industrial design.

08 Supply Chain Risk Thinking:

Consider the Rationality of Transnational Production

On November 5th, the dust settled on the U.S. election. As a high-unit-price technology product, the design and production of tool equipment must take into account the tariff risk caused by Trump's inauguration.

According to NYCD, taking 3D printers as an example, even if the materials come from domestic sources, the monthly salary of assembly line workers in Vietnam is 3.5K RMB (including social security), while in factories in Huizhou, China, the average wage is between 4.2K-4.5K RMB yuan. Despite the less than ideal power supply and supporting facilities, and the workers' proficiency, Southeast Asia and Mexico have still become new hotspots for industrial development. However, this could still potentially become a new growth point for a large number of tool manufacturers to save on tariff costs and overtake on a mass-production curve.

Industrial designers and local manufacturers are constrained by distance in terms of sample acceptance, materials, processes, and color matching. A professional industrial design team can understand and customize CMF schemes that are conducive to overseas cost reduction production, avoid using overly niche processes, and better leverage cost advantages. NYCD agency, with rich experience in supply chain development, can ensure that product design is aesthetically pleasing while the process is simple and easy to maintain. They are always ready to face multilingual challenges and provide thoughtful design services for the overseas factory teams of enterprises.

9. AI Experience Design

Discussing the trends and design creativity of tool-type products, how can we not mention AI?

To use desktop processing equipment effectively, a reserve of complex CAD materials is indispensable. However, this requires painstakingly searching for graphic materials through craft groups and CAD websites.

This day may never return. Bradley, former Internet product manager at xTool, believes that integrating AI functions in the supporting CAD software has the opportunity to serve as a cross-disciplinary tool, surpassing hardware to influence the blueprint material market for desktop-level processing equipment.

xTool's DesignFinder is a paradigm of community service design empowering hardware.

AI can provide unlimited material resources and optimize design schemes in real time. This tool is undoubtedly a very good product selling point for Western customers who are pursuing creative inspiration.

AI, beyond hardware, has raised the competitive threshold for software, making internet development a compulsory subject for every tool manufacturer, and bringing more possibilities for competition in 2025.

Now you have your product development you need to design 3D in CAM software to them for prototype testing and validation and, eventually, production. We can help.